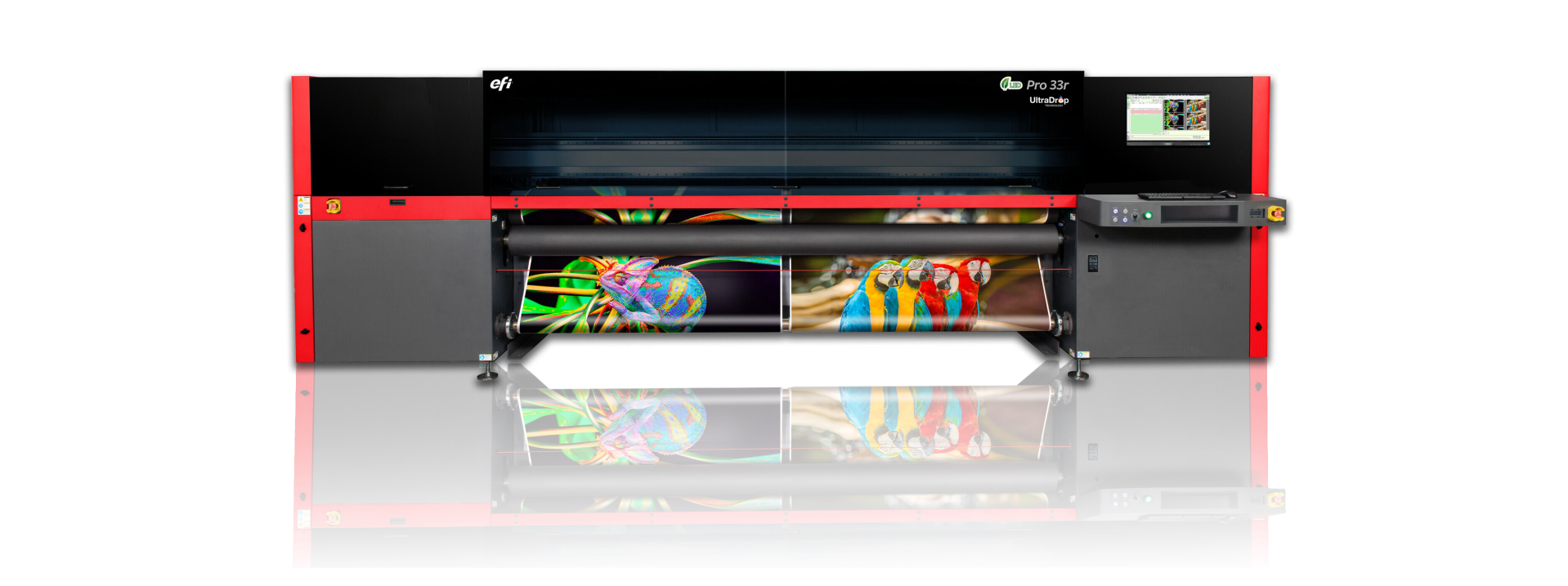

Brilliant applications. Stunning

capabilities. Awesome profits.

Combine the right creativity and skills with the capabilities of EFI’s digital inkjet printing equipment to accelerate

your success in capturing new and more profitable opportunities.

Press Releases

The latest press releases about EFI – the company, our partners, our brilliant customers, and the latest innovations in digital printing.

10 Apr-2024

EFI Brings Wide-format Solutions Designed to Help Sign Shops Drive Profits and Growth to ISA International Sign Expo 2024

21 Mar-2024

ImageData Group Targets Growth in Display Graphics Market with EFI Nozomi 14000 SD Super High-Speed Digital Press

19 Mar-2024